Understanding Bore and Stroke

Your engine's bore and stroke dimensions play a vital part in the way it produces power. Here's how

It's all very well saying this, that or the other is slimmer, narrower, shorter or more shiny than before, but sometimes it helps to explain things in more detail to really understand the benefits.

Earlier this year we were treated to an all-new R1. 'It's got radial brakes so it stops better!' we said. 'It's got underseat exhausts so it looks better!'. 'It's got a shorter stroke and a wider bore so it revs higher!' Okay, so it has. But how? And why? We churn out bore and stroke figures in our tech spec panels month in, month out, but what relevance do they really have?

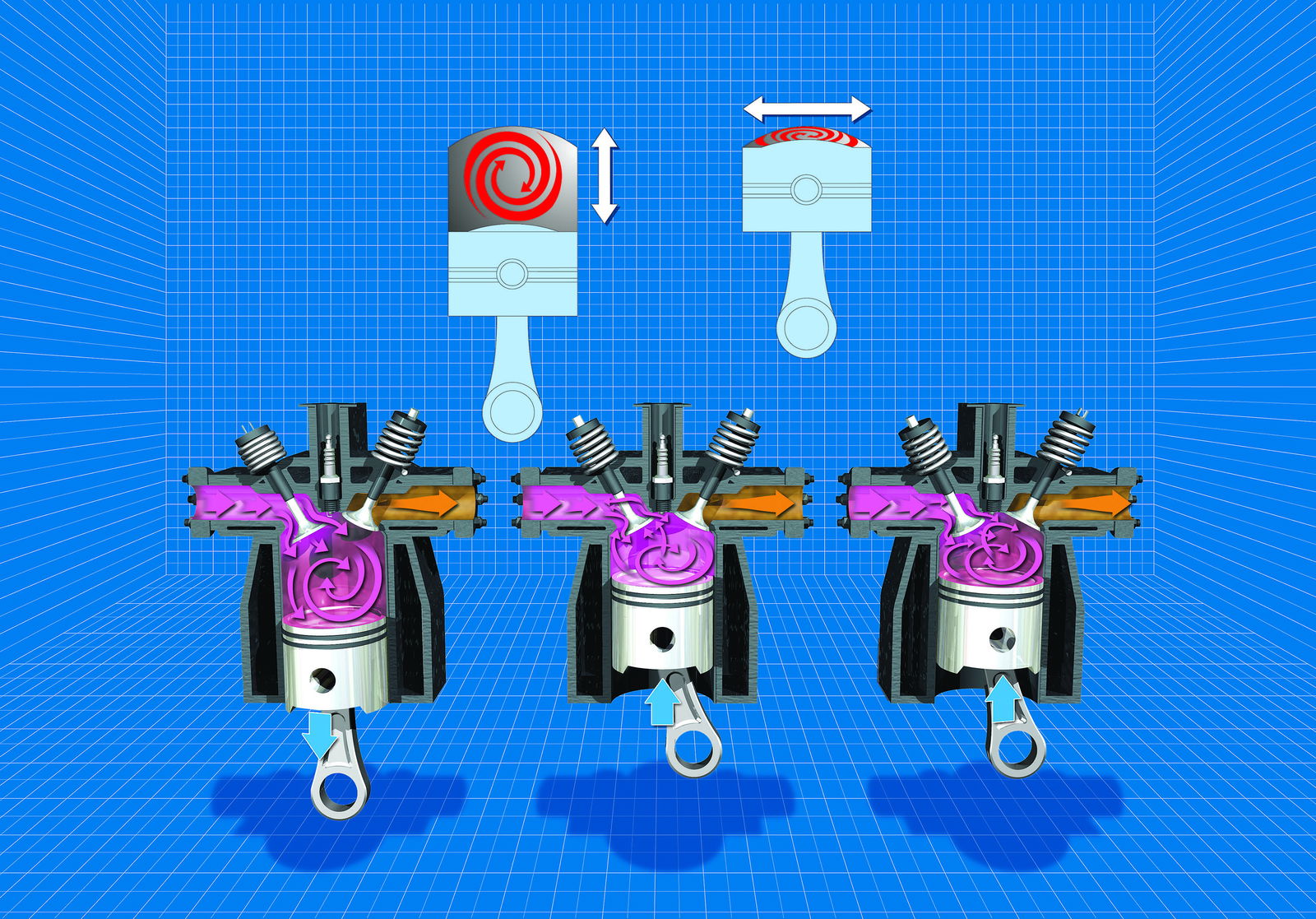

The relationship between an engine's bore and stroke determine, to an extent, how it makes its power. For a given capacity, 'long stroke' motors - ie those with a relatively long stroke in relation to the bore size - will tend to be relatively low revving but with strong low down power, while 'short stroke' or 'oversquare' motors - short stroke with a wide bore - will be able to rev higher. And, because more revs equal more horsepower (horsepower = torque x rpm divided by 5252, so increase the revs and the bhp increases too), manufacturers are always looking at ways of safely increasing the upper rev limit of their motors.

One of the major factors determining an engine's upper rev limit is piston speed. For every revolution of an engine, the piston moves up from the bottom of its stroke (bottom dead centre or BDC) to the top of its stroke (top dead centre or TDC) and back again. So in the case of the '04 R1, the 77mm wide piston goes from a standstill, travels 53.6mm up, stops, and comes back down again. At 10,000rpm it makes this journey just over 166 times each way every single second, at an average speed of 17.9 metres a second.

The stresses on a piston and conrod at high revs are massive. If the piston is forced to travel too quickly something's going to break. Put very simply, if you reduce the distance the piston has to travel - ie its stroke - it doesn't have to travel as fast and can make that journey more often. So that's what Yamaha chose to do with their '04 R1, reducing the stroke by 4.4mm and adding 3mm to the bore. Last year's R1 redlined at 11,750rpm. This year's redlines at 13,750, and makes its peak power 2000rpm further up the scale.

At that 13,750rpm redline, the R1's average piston speed over the 53.6mm stroke is 24.6m/s - that's just over 55mph in English. By way of comparison, the longer-stroke GSX-R1000 (bore 73mm, stroke 59mm), redlines at a lowly 12,250rpm, at which point its piston is travelling nearly as quickly as the R1's - 24.1m/s. Just 250rpm later, its piston has reached the same speed the R1's does1500rpm further round the dial.

But it isn't like bike manufacturers have only just worked all this out. It's only as time has moved on that production and material technology has allowed the manufacturing of components able to withstand such high engine speeds that engineers have been able to take better advantage of short stroke theory.

Of course it has disadvantages, one of which is that it makes the engine wider. See how the '04 R1's frame spars now loop over the motor rather than wrapping rond them? And by using all those revs to make

horsepower, power delivery, driveability and traction become serious issues, as does building a chassis to cope with it all. Then again, long strokes make engines taller. But look at the way that long stroke, 'low revving' Rizla Suzuki GSX-R1000 grunts out of slow corners in British Superbike racing...

Sponsored By

Britain's No.1 Specialist Tools and Machinery Superstores

When it comes to buying tools and machinery, you need to know you're buying from specialists who know what they're talking about.

Machine Mart eat, sleep and breathe tools and machinery, and are constantly updating their range to give you the very best choice and value for money - all backed by expert advice from their friendly and knowledgeable staff. With superstores nationwide, a dedicated mail order department and a 24 hour website offering quality branded items at fiercely competitive prices, they should be your first choice for quality tools and equipment.