What’s the next step for motorcycling tech - is 3D printing the way forward?

3D printed parts could become the next development in motorcycling, but the question is: would you trust a plastic part you built yourself in the shed?

MOTORCYCLING as an industry is developing at an extremely fast pace - whether it’s winglets to generate downforce, MotoGP influenced assist & slipper clutches, the introduction of electric motorcycles - it seems we are always looking for a new edge. Now, whether you say it’s searching for a new gimmick is down to personal opinion, but what’s next?

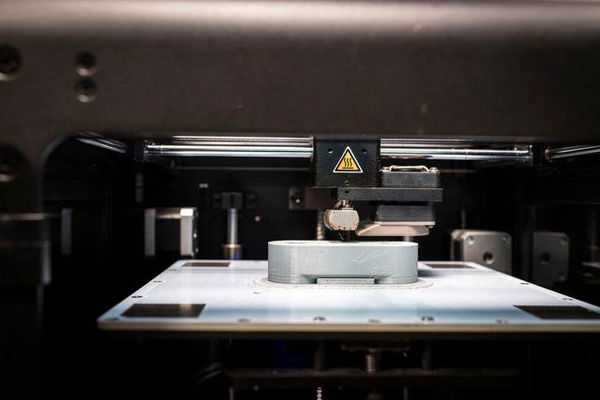

We think it could be 3D printing. Forget ink-jets and laser printers, we’re talking the much more advanced than that here. In the right hands, 3D printers can allow anyone to create anything their heart desires, whether it’s a cup-holder or a precision engineered race-spec part for a superbike.

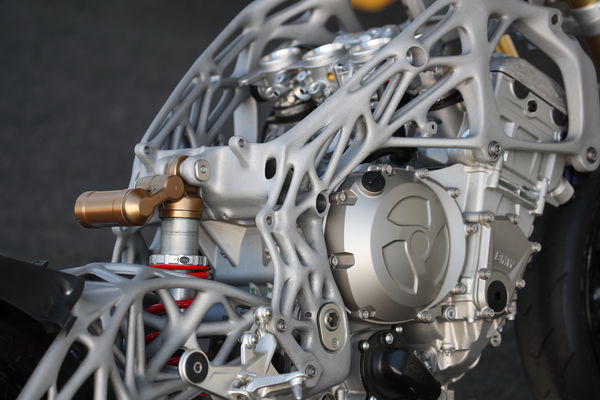

We’ve known about BMW Motorrad Motorsport using 3D printing trackside to give them the option of printing parts on the fly for a while now, and BMW has in the past shown the promise of 3D printing when they printed a full S1000RR frame. So, as seems to be the case, the pioneering tech used by factory teams in the various top race championships (BSB, WorldSBK, and MotoGP bikes) does tend to trickle down to consumer models, so will it be before long that we see a motorcycle that has a range of 3D printed parts?

WATCH every new motorcycle being launched this year!

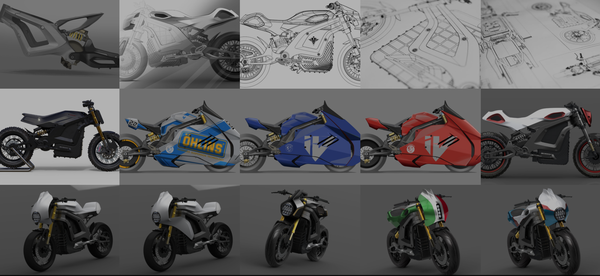

Well, there’s actually an electric motorcycle on the horizon with exactly that - 3D printed fairings and modular components that can be easily swapped around. This was recently covered in a story on the Tazzari group merging with Italian Volt, who have conceptualised the Lacama: a motorcycle that allows you to swap out fairings, seating (to go from single to 2 seats), and headlight setups. The ‘chameleon’ motorcycle opens the doors to new possibilities when it comes to 3D printing parts for the road, and gives the consumer a greater choice on the final style of their motorcycle at a decent price.

Would 3D printing bring old parts back to the market?

One plucky motorcyclist has in the past printed a choke lever for his motorcycle, simply because the part he needed wasn’t produced anymore - showing that in the face of adversity, ingenuity can prevail. As the technology progresses, there’s no doubt it could become a fantastic option for the industry, especially for classic and heritage models which may suffer from an ever-decreasing availability of original and aftermarket parts.

Image: 3D printed variations available with the Italian Volt Lacama.

There’s also then the option for new parts to be developed, CAD designs shared in Facebook groups across the world for those sharing interests in the same model. No doubt aftermarket designers will monetise their designs to be purchased and built at home - but that’s no different from ordering your part online. You just get to build it straight after at home.

A 3D printer will set you back around £200-300, but that’s for the basic models - I’d imagine the BMW Motorrad Team didn’t order theirs from Amazon - so purchasing a 3D printer with enough precision to manufacturer a vital component will be vital, and that’s going to be a bit pricier.

The caveat here is that a home 3D printer may not be capable of building a part with enough structural integrity and strength to withstand the external forces on the road - and if it’s a vital, stress-bearing part, you really don’t want it to snap. Some plastics can be reinforced with carbon fiber, but then we’re starting to talk much more advanced than the average Steve in his garage hunched over his RD350LC, who’s looking for a new exhaust bracket.

When asked about the 3D printing tech with their S1000RR, Marc Bongers, director of BMW Motorrad Motorsport, was quoted:

“The new components are printed as plastic variants and their functionality and ease of installation are checked directly on the bike. This process is now much faster than when we had to wait for parts to be manufactured in-house or externally and made available for evaluation on the track. It is also easier to gauge potential contact with surrounding parts than on a screen.”

So it’s by no means a fix-all permanent solution on trackside, and they still ship the final CAD design off to the factory to build a permanent metal or carbon part - but 3D printing technology allows the team to near-instantly develop and refine a part that would otherwise take much longer to design.

Where does this leave us, the consumer?

Of course, the question has to be asked, can you trust a 3D printed part? Well, if it’s good enough for a WorldSBK team… it’s probably going to be alright on the night!

Given the numbers of classic motorcycles and scooters on the roads that may be in need of a part that is no longer around, and with the technology developing day-by-day, I think 3D printing technology is absolutely something to keep an eye on. Whether it’s a manufacturer that picks it up for a new range, or the Lacama 3D printing their way into the market, the options are literally endless. It’s like having a factory in your garage that can build anything you need, so turning to a 3D printer could become the future option for all you fixer-uppers and tinkerers - but you just may have to wait for the technology to develop first.