Kawasaki working on supercharged two-stroke with crossplane crank!

Patents reveal that Kawasaki is plotting a return to two-stroke power, with supercharging, and a crossplane crank!

PATENTS found on the Japanese Patent Office (JPO) have revealed that Kawasaki is looking to the future, with a new design of two-stroke engine that features a host of innovations.

With ever-tightening global engine emissions regulations, creating a cleaner-burning engine that doesn’t lose out on power is a motorcycle designer's most important quest. From hybrids to superchargers, two-strokes to four-strokes, anything, it seems, is fair game to try out in the quest for environmentally friendly performance.

Kawasaki ZZ1400 first impressions

More often than not, engineers will look at combining one piece of ground-breaking tech alongside a conventional engine design, to help push the performance to an acceptable level. Never though, have we seen one engine design that pretty much uses them all – until today.

This patent from the JPO shows a revolution in motorcycle engine design, and if it makes it to market, it’s surely going to be one of the most innovative pieces of engine design ever.

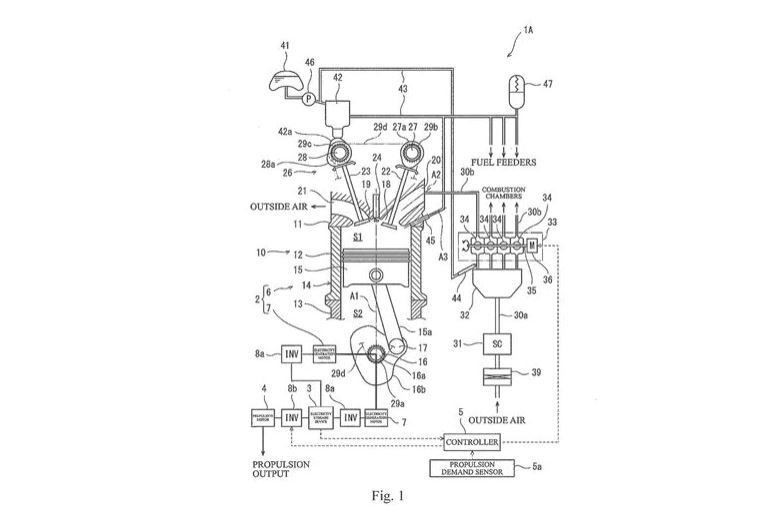

The patent shows a supercharged, four-cylinder, two-stroke, crossplane, engine with poppet valves, and double overhead camshafts! The other big news is that this engine is actually powering a hybrid power system, not the rear wheel.

While two-strokes are often singled out for being dirty emissions generators by governments and regulators, if given a set RPM window to run at they can actually be very clean, producing fewer emissions than a conventional engine. As the new design seems destined for a series hybrid – where the engine charges the batteries and doesn’t power the wheels – the engine would only have to work within a specific window of revs.

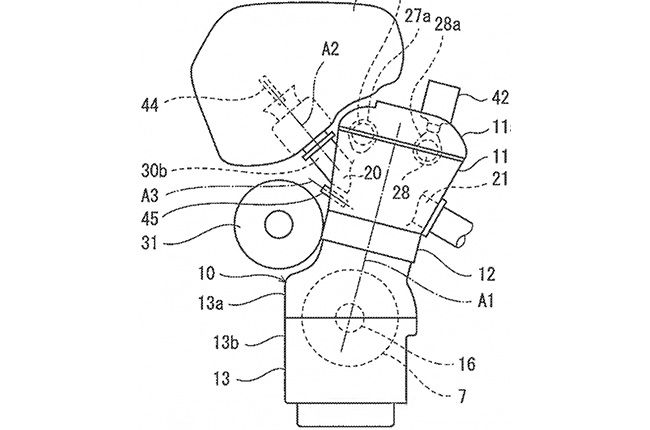

To help make the engine burn cleaner, the unit is fitted with a supercharger, increasing the air pressure in the intake and helping the engine to expel the exhaust gases quickly. Another innovation of the unit is that instead of using ports within the cylinder walls to move the gases in and out of the combustion chamber, the new design uses valves mounted at the top of the combustion chamber, opening them both at the same time, allowing fresh charge air to be drawn in and exhaust gases to be expelled in one action.

By precisely timing this operation, the engine can accurately allow the exact amount of air/fuel in to the engine to optimise the burn in the combustion chamber.

The engine also has a crossplane crank and a 1,3,2,4 firing order, with each piston producing power every 360°. The crossplane crank will help the engine to run smoothly, with no two pistons firing at the same time.

With so many innovative features, it’s almost a shame Kawasaki aren’t eyeing the same tech up for their conventional motorcycles, where the engine directly powers the rear wheel, although it’s worth remembering, the clever tech in this engine is there only for the engine to be efficient at a set RPM, not super powerful across the entire rev range.

With engines such as this commonplace in other modes of transport, boats have used the method for some time and some trains use the method, trying to estimate the efficiency is not too hard, with some experts putting the efficiency of this engine at over 50%.