Carbon-fibre for the masses takes a step closer

Award-winning swingers could be coming to every bike near you

BMW’s HP4 Race might be one of the most exotic and desirable motorcycles on the planet but its track-only designation, regular engine rebuilds and eye-watering price tag means none of us will ever get to experience it.

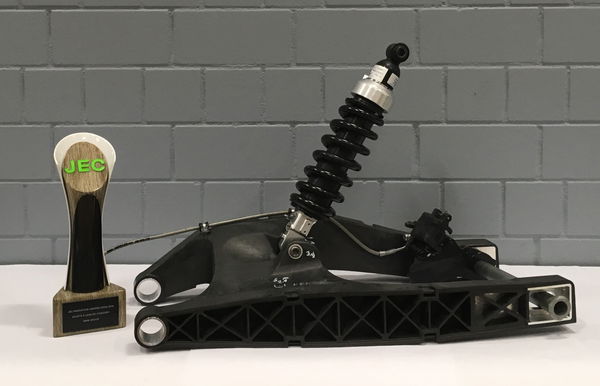

Of course, its carbon-fibre chassis is one of the HP4 Race’s key features. Now BMW has got ideas to make that technology available to the masses, and it’s revealed this swingarm to prove it.

It looks like the arm is designed to fit BMW’s lowliest model, the G310R. The lack of any rising-rate linkage for the rear shock, plus the fact it’s clearly for a chain-drive bike rather than a shaft, leave few other possibilities.

The design was presented with the 2018 JEC Innovation Award in the Sports and Leisure category. The JEC Group is the world’s leading specialist organisation in composite material development and manufacture.

BMW’s latest swingarm project was intended to develop a system to allow high-volume production of carbon-fibre in structural components. In the case of the swingarm itself, the solution was a type of injection moulding, using carbon-fibre reinforced plastic, with extra reinforcement using carbon-fibre tape

Project manager Elmar Jäger explained: “We opted for chassis components under continuous load since the requirements involved are especially demanding. While car chassis parts are concealed, the visible motorcycle rear swinging arm was ideal for our project since the forces at work are immediately evident.

"Our production technique uses CFP in the form of high-strength endless fibres where this is required by the stress pattern, while an injection mould part with short CFP recycling fibres is used where the stress levels are not as high. In this way, we developed a cost-efficient design that can be scaled according to requirements by inserting endless fibres with varying levels of strength in the same tool.

"These were the points that impressed the international jury. The insights we gained from this motorcycle component are equally valuable from the point of view of car development and can be applied accordingly.”

Dr Joachim Starke accepted the award and said: “In addition to achieving weight benefits and cutting costs significantly, we also managed to develop a technology that allows precise configuration of component properties by using a variety of composite and metal inserts. All this impacts significantly on cost efficiency (component costs) as well as part properties(strength and stiffness).

"With this example of the rear swinging arm, the project has allowed BMW Motorrad to take on a pioneering role within the motor vehicle industry. The insights gained consistently build on the BMW i3 as the basis for the use of CFP in serial production and include interesting aspects in terms of the future development of new BMW motorcycles and automobiles.”