Has Yamaha Gogoro deal just transformed the idea of electric bikes?

As Gogoro and Yamaha join forces to make electric bikes with swappable batteries, Visordown asks: Is this the first step to truly usable electric motorcycles?

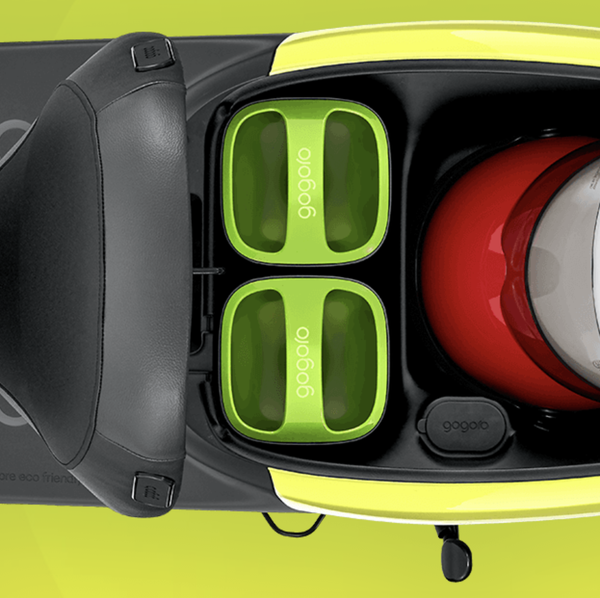

GOGORO and Yamaha have teamed up to make electric motorcycles and scooters that use a revolutionary swappable battery. This means recharging is a simple (and quick) as swapping out a power pack and riding on your way.

Since the dawn of the electric motorcycle, naysayers have long pointed to multiple reasons to put them off plugging into the electric revolution. These include limited range, mains power availability and recharge times, the latter of which can be either a fast charge the equivalent of time spent in a McDonalds drive-thru to a more leisurely juice up that’s like ordering a pizza on New Year’s Eve.

Each is a limitation enough to stick to convention and fossil-fuel powered motorbikes, but the solution to these compromises may have finally been sourced… and it’s actually really simple!

Rechargeable, removeable batteries that can be placed on a charge whilst you use the other one – like a camera with two power packs.

Who is Gogoro and why is Yamaha teaming up with it?

Well now it looks like this e-bike nirvana is nearly upon us, as Taiwanese EV company Gogoro has teamed up with a number of motorcycle manufacturers in a deal that will see them all use the Gogoro swappable batteries and the use of its electric vehicle charging infrastructure – and the biggest name of them all is Yamaha.

The other marques are more bit-players in the bigger picture of motorcycling, Aeon Motor and PGO, but Yamaha’s inclusion in the list makes the whole deal a lot more interesting indeed. First of all, it means Yamaha are taking an electric future seriously enough to start the ball rolling on this deal, way before the rest of the establishment has pulled the trigger.

Gogoro is already a manufacturer of a range of funky-looking scooters which have been designed with a youthful, eco-conscious market in mind, with features that include only being able to unlock the machine via your phone's biometrics and interactive app support.

Secondly, as we all know – Yamaha don’t just make small lightweight electric scooters. They make big petrol powered bikes that sell in droves, meaning a big, powerful electrically powered sports or adventure bike that uses this platform, could be a very real possibility.

Why battery swapping - rather than recharging - could be the future for e-bikes

The battery swapping bikes hold a number of benefits over the current plug-in-and-wait method, and it’s not just the speed it takes to charge up either. The fact that the batteries used are not owned by the person swapping them – they always belong to the Gogoro and the punter simply borrows or rents them. This means the cost of the battery, which can be anything up to half of the bike’s total value, could be discounted off the price of the vehicle. With the rider only paying for the electricity used and a nominal charge for battery maintenance.

Another plus-point comes in the form of weight, or lack of it. With such quick recharge times, users could opt for lighter, less power-laden batteries and a lighter bike. The trade-off would be more frequent battery stops but, when it takes a few seconds to swipe a card and swap the unit over, who cares!

Are there any limitations to battery swapping?

It isn’t all good news though, with one problem being you might not know what sort of state the cells within the battery are in. Batteries degrade over time; the constant charge and discharge cycles weaken the bonds within the cells. Eventually, this process wears out the cathode, which results in reduced capacity. A high-end lithium-polymer battery can lose about 20 percent of its capacity after 1000 charge cycles.

There is a possible solution though that companies could use: If the charging station could determine the internal condition of the battery, makers could indicate what the capacity within the battery is, offering those who ride infrequently or over shorter, less draining journeys the chance to use a battery with a lower capacity for a lesser amount. Leaving more of the better condition batteries for those of us that want to go hunting apexes and record 0-60 times!

Electric transport has come on leaps and bounds in the last decade, almost unrecognisably so, and whilst the two-wheel market has been reticent to the idea of electric machinery from a practicality and purist point of view, ideas like this appear to be a genuine shift direction to bridge that chasm.