Yamaha announces new recycled material for motorcycle production

Yamaha has announced the completed development of a new recycled polypropylene material which it will begin using in motorcycle manufacture this year.

Yamaha has announced its adoption of a new recycled polypropylene in its manufacturing processes for its powered two-wheelers.

The adoption of the new recycled polypropylene (PP) for Yamaha comes at the conclusion of the Iwata marque’s development process of the material, which Yamaha describes as “successful” in a press release.

While recycled PP is not entirely new to Yamaha, the new material it has developed “offers even higher levels of strength and quality looks compared to conventional recycled materials,” Yamaha says.

Additionally, Yamaha says that its recycled PP is made from “raw materials, which have not reached customers, and are supplied especially for their use in recycled final materials,” and have “no risk of containing environmentally hazardous substances.”

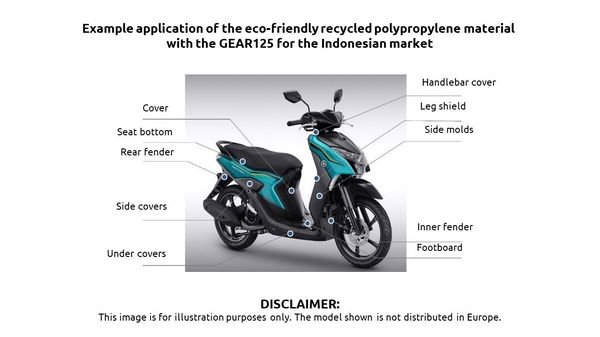

The recycled PP will be used by Yamaha in the construction of the main exterior bodywork of its powered two-wheelers.

More specifically, the newly-developed recycled PP will be used to make the bodywork of consumer motorcycle models marketed in ASEAN markets, such as the Gear125 (pictured above). (ASEAN is the Association of Southeast Asian Nations, a 10-member political and economic union of the Southeast Asian countries: Brunei, Cambodia, Indonesia, Laos, Malaysia, Myanmar, Philippines, Singapore, Thailand, and Vietnam.)

While its use is limited to exterior bodywork at the moment, the new recycled PP could also be used for “areas requiring greater aesthetic appeal,” Yamaha says, and it also plans to expand its use into other product areas.

This latest news from Yamaha follows the announcement last year of its adoption of a plant-based resin for use in its watercraft engines, with the possibility of bringing it to motorcycle engines at a later point.