Are camless engines going to be the next big thing?

Visordown takes a look at what could be the next big thing in motorcycle engineering

IF you are familiar supercars, the phrase camless engine or FreeValve engine might mean something to you. If you’re not well versed in the world of four-wheeled performance, you may have heard the of the phrase pneumatic valves from the world of MotoGP.

The premise is basically the same – to operate an engine's intake and exhaust valves without the use of any old-school tech like chains, cams or gears.

Here’s why we think that camless engines could be the next big thing to revolutionise motorcycle engineering.

How does a camless engine work?

Before we go through why we think this could be coming to a showroom near you soon, let's take a look at how the camless engine works.

In a camless engine, charge gases and exhaust gases are introduced and expelled from the engine in the conventional method, via valves opening and closing at a pre-ordained time in the top of the combustion chamber. It’s the method with which the cams are opened and closed which makes this type of engine so interesting.

Instead of using rotating cams that are driven from the engine’s crank to actuate the valves, a camless engine uses air pressure above and below a piston that is connected to the valve to operate it. There are also some examples that use electromagnets to operate the valves, although these are less common.

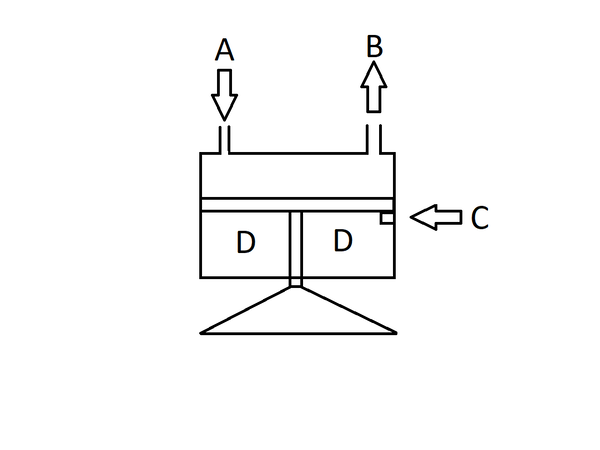

On the, fairly crude image above, A is the inlet into the chamber above the piston, B is the outlet, C is the locking pin and D is the below-piston air reservoir.

Two open the valve a signal will pass to a valve allowing a flow of high-pressure air into the area above the valve and the piston. This air will be at a higher pressure than the air below the piston, forcing the valve into an open position. Once the desired amount of valve lift and duration has been achieved, the air is released from the chamber above allowing the air pressure below the piston to force the valve shut.

In the image above there is also a pin located at the right of the actuator, it’s thought this is one of the ways manufacturers stabilise the piston when open and adjust valve lift when required. That much we don’t 10o percent know as they understandably keep those cards pretty well guarded.

What are the advantages of a camless engine?

A camless engine has a multitude of advantages over a standard camshaft is driven engine and the main one that makes me think we could see them in bikes soon is efficiency.

Efficiency

To start with, camless motors have much less parasitic load imparted on the engine; with no cam-chains, gears or camshafts to rotate, more of the engine’s torque can be used for moving and not moving internal parts.

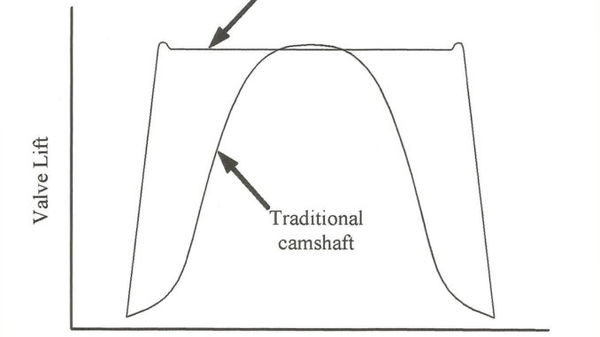

A camless engine also gains because the duration and height of the valve lift can be much more accurate than with a standard camshaft. The lobes of which must be rounded in shape, meaning the valve lift is always going to be compromised in some way as the engine waits for the valve to open fully.

Because the camless engine uses accurately delivered squirts of pressure to open the valves, they can open much more cleanly and at any time the fuel management deems necessary for optimal operation.

The image above shows a standard camshaft driven unit’s valve opening with a camless engine.

Because the valve opening and lift are now precisely timed, the engine management system can now more accurately determine how much fuel is required to achieve the most efficient combustion for a given engine RPM.

A camless engine can also switch off some of its cylinders much easier than a conventional engine. If the road speed drops below a set parameter, two of the four cylinders will open their intake and exhaust vales removing compressions and allowing the cylinder to move up and down more freely. The fuel injection can also be turned off at this point to prevent washing the oil from the cylinder bores. Once the engine requires the use of the two cylinders again the valve recloses, and the combustion cycle begins.

Packaging and power

A camless engine is also a much smaller and compact unit, with some camless care engines saving up to 30% weight when compared to a conventional engine of similar displacement. FreeValve, a sister company of Koenigsegg, has designed a turbo-charged engine that was 1.6l in displacement, yet it produced 230hp, 240ft-lb of torque. That engine was almost half the size of a conventional engine yet 30 percent more fuel-efficient and saw a 50 percent reduction in emissions.

Greta Thunberg would definitely approve!

When could we see a camless engine on a motorcycle?

Aside from MotoGP using a similar type of valve actuation for some time now, it’s not clear when the mainstream manufacturers will adopt this tech in the road bikes we can ride and buy. MotoGP always provides a drip-down of tech from the race bikes to the road, it always has done and, in my mind, always will, although I feel it’ll be the industry having its hand forced that causes tech like this to be adopted.

With ever-tightening emissions regulations and a consumer’s desire to have more power, speed and efficiency; simply increasing displacement and remapping fuelling to circumnavigate the regulations will become a task too much. Engineers and designers will have to look at other ways of solving the problem of power vs emissions.